Simple dry mortar production line

Zhengzhou Yishang Machinery Equipment Co., Ltd., a dedicated manufacturer in the construction equipment sector, is pleased to introduce its highly efficient and economical Semi-Automatic Simple Dry Mortar Production Line. Designed specifically for startups, small to medium-sized enterprises (SMEs), and contractors aiming to establish in-house mixing capabilities, this plant delivers a reliable output of 5-6 tons per hour. It represents an optimal balance of performance, affordability, and footprint, making quality dry mortar production accessible and profitable.

Core Design Philosophy: Simplicity, Reliability, and Value

Our engineering team developed this line with a clear focus: to eliminate the barriers to entry for dry mortar manufacturing. We understand that new ventures require solutions that minimize capital outlay, conserve factory space, and yet deliver consistent, marketable product quality. This compact dry mortar production line.mp4 embodies this philosophy. It strips away unnecessary complexity without compromising the essential processes of precise batching and homogeneous mixing. It is not merely a collection of machines but a complete, integrated dry mortar mixing plant solution, pre-configured for swift installation and ease of operation.

Key System Components and Technical Advantages

Precision Raw Material Handling and Weighing System

The heart of any reliable dry mortar equipment is accurate batching. Our line features a robust raw material weighing system. Key components include:

Bagged Cement/Powder Silo: A compact, elevated storage hopper designed for manual feeding of bulk powders like cement or limestone filler. Its strategic height facilitates gravity-fed discharge into the weighing system.

Weighing Hopper with High-Precision Sensors: This central hopper is suspended on professional load cells. It receives materials from the storage silo and auxiliary additive feeders. The integrated control system ensures weighing accuracy within ±1%, guaranteeing strict adherence to your formulation for every batch, which is critical for product performance.

Manual Additive Feeder Stations: Dedicated, small-capacity hoppers with manual gates allow operators to accurately introduce minor ingredients like cellulose ether, re-dispersible polymer powder (RDP), or pigments. This design ensures even trace additives are properly accounted for in the total batch weight.

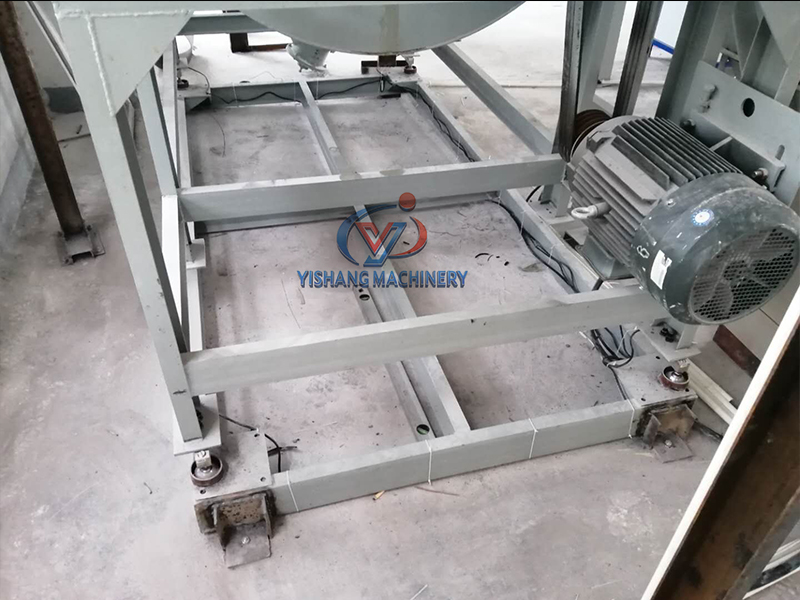

Efficient Mixing and Conveying Core

After precise weighing, the batched materials are efficiently transferred to the mixing unit.

Ribbon Mixer: We employ a double-shaft paddle mixer or a horizontal ribbon blender. This type of dry mortar mixer is renowned for its strong, forced mixing action. It quickly achieves a homogeneous blend of all components—from the major cement and sand fractions to the minute additive particles—within a cycle time of 3-5 minutes per batch. This ensures every bag of final product has uniform quality.

Discharge and Packing: The homogenous mix is discharged directly into a waiting bagging machine (optional) or into big bags/manual packing stations. The streamlined process minimizes material handling and potential segregation.

Unmatched Product Advantages for Our Clients

Compact Footprint & Space Efficiency: This is a primary benefit for workshops with limited area. The entire dry mortar machinery layout is vertically and horizontally optimized. By utilizing a vertical design for storage and weighing, the production line occupies a minimal ground area, typically under 50-80 square meters. This allows our clients to maximize their valuable production space.

Low Initial Investment & Rapid ROI: We have consciously designed out the high costs associated with full automation, such as large bulk silos, pneumatic conveying systems, and complex PLC controls. This simple dry mortar production line focuses on essential functionality. The result is a significantly lower capital requirement, making it the most cost-effective entry point into the dry mix mortar manufacturing industry. This low barrier to entry allows businesses to start generating revenue quickly, ensuring a faster return on investment.

High Production Efficiency & Consistent Output: With a proven capacity of 5-6 TPH, this line is far more efficient and consistent than manual mixing methods. The semi-automatic batching and efficient mixing cycle enable steady, predictable output. This efficiency allows our clients to meet daily demands reliably, fulfill orders on time, and scale their operations predictably. It transforms production from a labor-intensive, variable process into a controlled, industrial operation.

Operational Simplicity & Low Maintenance: The control system is user-friendly, often based on a simple electrical control cabinet with clear indicators. Training for operators is straightforward. Furthermore, the mechanical design prioritizes durability and ease of maintenance. With fewer complex components like dense-phase pumps or automated valves, maintenance costs and downtime are drastically reduced, contributing to higher overall equipment effectiveness.

Formula Flexibility & Quality Assurance: The system is perfect for producing a wide range of standard and specialty dry mortar products, including Tile Adhesive, Wall Putty, Plastering Mortar, Masonry Mortar, and Grout. The precise weighing system is the cornerstone of quality assurance, ensuring that every batch meets the required specifications and builds your brand's reputation for reliability.

Ideal Application Scenarios

This Yishang 5-6 TPH line is perfectly suited for:

New entrepreneurs entering the building materials market.

Construction companies aiming to produce mortar for their own projects.

Small building material retailers expanding into production.

Regional producers focusing on local market supply.

Pilot plants or testing facilities for new formulas.

Conclusion and Commitment

Zhengzhou Yishang Machinery’s 5-6 TPH Dry Mortar Production Line is more than just equipment; it is a strategic partner for your business growth. It delivers the core benefits of industrialized production—consistency, efficiency, and quality—while respecting the constraints of budget and space.

We invite you to contact our sales and engineering team to discuss your specific project requirements. Let us help you configure the optimal dry mortar plant solution to launch or expand your profitable dry mortar manufacturing operation.

Whatsapp:++8615137127837

WechatID:+8615137127837

Email:[email protected]

Alibaba Store:

https://zzyishang.en.alibaba.com