Simple dry mortar production line

1. Thorough and Gentle Mixing Action

The unique ribbon agitator design ensures a three-dimensional mixing movement. It gently lifts and folds the dry materials (like cement, sand, and additives) from the center outwards and from the ends inwards. This creates a homogeneous, streak-free blend without damaging the particle size of the sand or fillers, which is crucial for mortar quality.

2. Ideal for Small to Medium Batch Production

Horizontal ribbon mixers are perfectly suited for small-scale operations, pilot plants, or producing specialized mortar batches. Their compact footprint and efficient design make them a cost-effective solution for businesses that do not require the massive output of a full tower plant.

3. Rapid Discharge and Easy Cleaning

The full-length discharge valve at the bottom of the mixer allows for a rapid and complete emptying of the batch. This minimizes cycle time and significantly reduces material residue or cross-contamination between different recipes. The smooth interior surfaces and accessible design also make cleaning and maintenance straightforward.

4. High Versatility for Complex Recipes

This type of mixer excels at handling formulations with varying particle sizes and densities, as well as those requiring low-percentage additives (like fibers or polymers). The gentle yet thorough action ensures these minor components are evenly distributed throughout the entire batch without segregation.

5. Robust and Low-Maintenance Design

Built with a simple yet sturdy mechanical structure, horizontal ribbon mixers are known for their reliability and long service life. They have fewer complex parts compared to some other mixer types, leading to lower maintenance requirements, reduced downtime, and overall lower operating costs.

Experience fast cycle times and a perfectly uniform mix in just 3-5 minutes. The robust three-layer ribbon agitator thoroughly blends even complex recipes. Built for longevity with reinforced blades and drum walls, and powered by a reliable ZQ gear reducer, this mixer is engineered for demanding continuous production.

Designed for continuous duty with minimal downtime. From the durable piston-type air compressor providing stable pneumatic power to the heavy-duty construction of the mixer itself, every component is selected for reliability. This robust design translates to lower maintenance costs and greater long-term operational stability.Piston-Type Air Compressor: Durable, low-maintenance design for consistent pneumatic performance.

✅ High Accuracy: Precise weighing and mixing for consistent product quality.

✅ Durable Construction: Thickened steel and wear-resistant components for longevity.

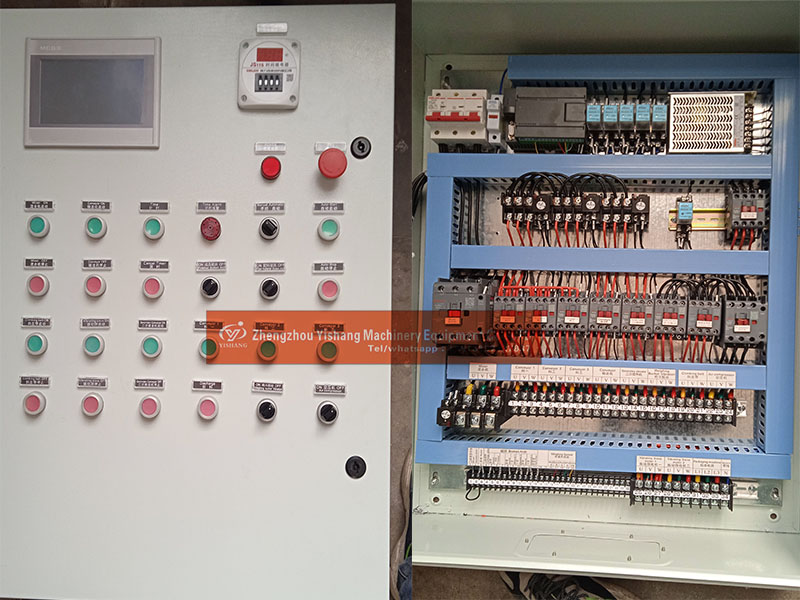

✅ Automated Efficiency: Reduces labor costs and increases production speed.

✅ Easy Maintenance: Simplified design for minimal downtime.

✅ Customizable Options: Adjustable motor power, capacity, and packaging solutions.

✔ Tile Adhesive Manufacturing

✔ Wall Putty Production

✔ Dry Mix Plaster & Mortar

✔ Self-Leveling Compounds

✔ Waterproofing & Grout Mixes

Our dry mortar mixing and packaging line is engineered for maximum output with minimal waste. Whether you produce tile adhesive, wall putty, or specialty mortars, our system delivers reliability, precision, and efficiency.

📞 Contact us now for a customized solution tailored to your production needs!+8615137127837

Whatsapp:++8615137127837

WechatID:+8615137127837

Email:[email protected]

Alibaba Store:

https://zzyishang.en.alibaba.com