Installation and use of simple dry mortar production line

2024-05-13

2024-05-13

Installation and use of simple dry mortar production line

Dear friends:

Hello, welcome to become the company's user, thank you for your trust in us, you choose is my company's production of "YISHANG" multi-function screw dry mortar production line, the company will be happy to serve you.

Tools and spare items required for installation:

1, 100A three-phase four-wire moulded case circuit breaker (connected to the main gate), 63A three-phase miniature circuit breaker two (connected to the host and air compressor), 40A three-phase miniature circuit breaker two (connected to two lifts), 4P miniature circuit breaker 40A (connected to the packaging machine), 6 square single-core copper wire 10 meters for serial connection of each switch, One small electric box (400*500*200), four 10mm expansion screws, one hammer drill, one 10mm drill bit, 1m guide rail, 12-14, 14-17, 19-22, 22-24 open box wrench, one 250mm adjustable wrench, 10m iron wire, one handwrench, one wallpaper knife, one flat-head screwdriver each, 2 rolls of electrical tape, a barrel of butter, a butter gun, a 0.9m3/min air compressor (joint matching), 10mm plastic transparent gas pipe 30m, a quick gas pipe tee, two sets of iron 10mm gas pipe joints, a blow (wind) gun, and 2 rolls of raw material.

2, the main motor connection wire is 4 square three core copper wire, a screw elevator electromechanical electromechanical wire is 2.5 square three core copper wire, packaging electromechanical electromechanical wire is 2.5 square four core copper wire. The cable line depends on the position of the machine and the distance from the power bus

3, if the reducer of the mixing machine is a cycloidal needle reducer, you need to buy 46# oil (anti-wear hydraulic oil) 4 liters of two barrels.

Installation procedure

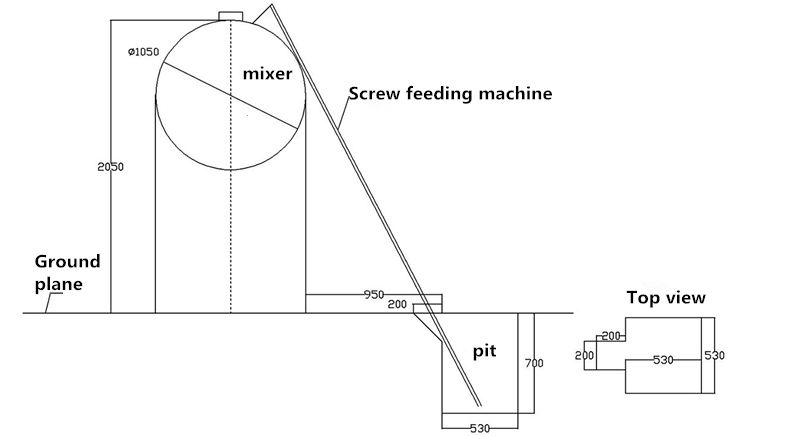

I, according to the layout plan of the user's site, the multifunctional mixer host is placed in the pre-selected place. Note: Several factors should be taken into account when selecting the location of the mixing machine: 1, the raw material storage area and the finished product storage area are more convenient. 2. Reserve the device maintenance channel. Generally, the width of the maintenance channel is 0.8 meters. (Overall diagram)

II. After the mixing machine is placed in place, take the center of the feeding port of the mixing machine as the standard, and measure 0.95 meters outward from the edge of the mixing machine. This is the edge of the hopper pit on the screw feeding machine. Pit size is shown in the figure: 0.53m (length) * 0.53m (width) * 0.7m (depth)

Note: After the pit is dug, if there is water seepage inside the pit, it needs to be waterproof treatment.

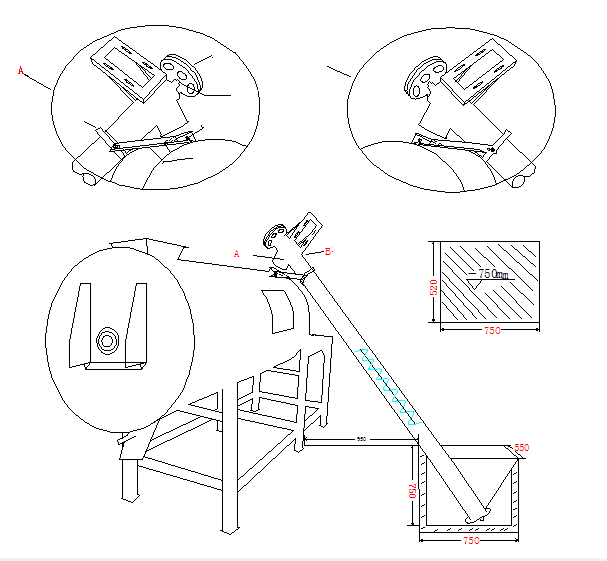

Before digging a good pit into the elevator, the bottom of the elevator butter tube should be good! (as shown in the picture)

III, after the pit is dug, the screw feeder is put into the pit, and the hopper of the feeding machine is level or higher than the ground (within 10cm from the control). As the picture shows:

IV, after placing, connect the screw feeder and the mixing machine with the hoop, and tighten the screws. The discharge port of the screw feeder and the feed port of the mixing machine are connected with a soft connection and tied with a wire. After the connection is complete, use a dust-proof breathable cloth bag (dust bag) to tighten the other feeding port above the mixing machine to prevent dust. As the picture shows:

V, after the connection, find the manual butterfly valve, and use the screw to link the secondary lifting and manual butterfly valve and the discharge port of the mixing machine. Note: When the manual butterfly valve is placed, please note that the manual butterfly valve is opened when the wrench is upward. As shown in the picture:

VI. After putting it in place, use the hoop to link the secondary screw feeder and the finished product warehouse. The discharge port of the screw feeder and the feed port of the finished product bin are connected with a soft connection and tied with a wire. As the picture shows:

VII. After the link is good, cover the other two feeding ports on the finished bin and another feeding port on the mixing machine with a dust-proof and breathable cloth, and tie them tightly with a wire.

VIII, move the automatic packaging machine under the finished product warehouse. After adjusting the position of the packaging machine in accordance with the principle of packaging convenience, take out the cloth bag of the packaging machine and link it with the material opening of the finished product bin, and tie it with wire, remember to tie it tightly.

IX, link each motor wire. Note the reverse turn. The mixing machine stands in the direction of the discharge port to see that the mixing shaft turns counterclockwise to turn positive. The automatic packaging machine can follow the arrow direction marked on the case. The direction of the tip of the spiral blade of the screw feeder is positive. (The screw feeder looks from the bottom up, and the belt turns counterclockwise for positive rotation)

Precautions for operation and use

1, when starting, the power supply of the mixing machine should be turned on first, and the mixing machine is strictly prohibited from starting with load. Next, turn on the elevator once, and you can load the material after the power is turned on. The mixing machine sets its own time according to the nature of the material used by its customers. After the mixing is finished, open the secondary hoisting machine power source and open the manual butterfly valve at the discharge port of the main machine.

2. After the material enters the finished product warehouse, open the manual valve under the finished product warehouse, open the automatic packaging machine, and packaging can be done.

3, daily maintenance: reducer regular refueling, it is best to replace once half a year, check the oil level within half a year, not enough position in time to supplement. The bearing at both ends of the main machine and the screw feeder add butter once a week.

Whatsapp:++8615137127837

WechatID:+8615137127837

Email:[email protected]

Alibaba Store:

https://zzyishang.en.alibaba.com