Features and Advantages:

1. Fully automated operation for enhanced labor efficiency.

2. High-precision weighing ensures consistent bag weight.

3. Rugged design guarantees reliable, continuous performance.

4. Dust-free sealing system for a cleaner working environment.

5. Simple to operate and maintain, minimizing downtime.

6. Versatile packaging for various mortar types and bag styles.

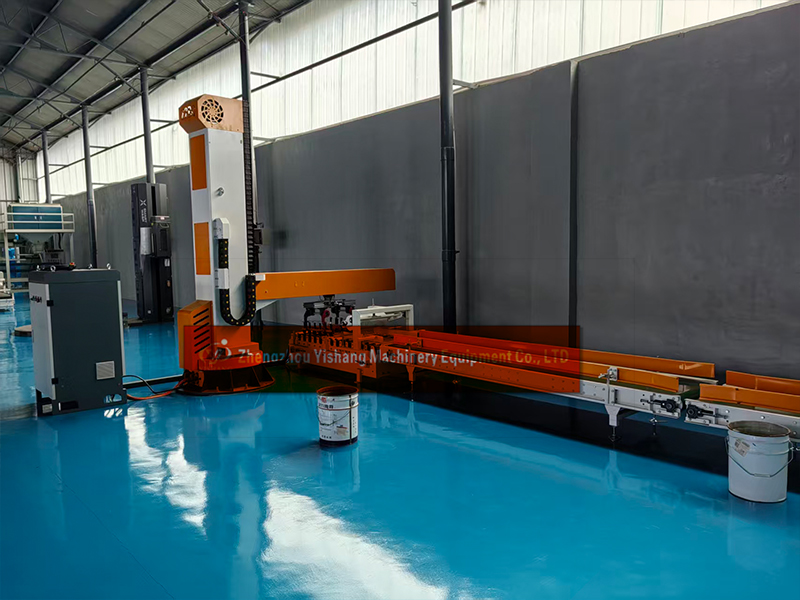

Fully Automatic Dry Mortar Packing Machine Line

Meta Description: Discover our integrated Automatic Dry Mortar Packing Machine Line. Featuring a high-speed Valve port dry mortar packing machine, Automatic Bag Placer, Screw Conveyor, and robotic palletizer. Achieve dust-free, high-capacity packaging from bagging to palletizing.

Complete Automation for Your Dry Mortar Production

In the competitive construction materials industry, maximizing efficiency and ensuring product integrity is paramount. Our Fully Automatic Dry Mortar Packing Machine Line is a seamlessly integrated solution designed to automate your entire packaging process. From receiving the raw material to dispatching a perfectly stacked pallet, this line enhances productivity, reduces labor costs, and guarantees a clean, consistent operation.

This state-of-the-art system is engineered for handling a wide range of dry, free-flowing powders, including tile adhesives, plaster, grouts, self-leveling compounds, and cement.

Core Components of the Packaging Line

1. Valve Port Dry Mortar Packing Machine

The heart of the line, our Valve port dry mortar packing machine, is engineered for precision and cleanliness. It features a specialized filling system that connects directly to the valve of the pre-formed bags, ensuring a completely dust-free operation. Its advanced weighing system guarantees high-speed filling with exceptional accuracy, ensuring every bag meets your exact weight specifications.

2. Automatic Bag Placer

Achieve true hands-free operation with our Automatic Bag Placer. This intelligent system automatically picks up empty valve bags from a stack and places them precisely onto the filling spouts of the packing machine. By eliminating manual bag feeding, it not only reduces labor requirements but also significantly increases the line's overall speed and operational safety.

3. Belt Conveyor

For a consistent and reliable material supply, our enclosed Screw Conveyor acts as the vital link. It efficiently transports dry mortar from your storage silo or mixer directly to the hopper of the packing machine. Its robust design prevents material segregation and contamination, ensuring a uniform product flow that is essential for maintaining high packaging accuracy.

4. Palletizer

Completing the automation cycle, our robotic palletizer efficiently organizes the filled bags into stable, uniform pallet loads. It can be programmed to create various stack patterns to optimize stability for transport and storage. This final step eliminates the most labor-intensive part of the process, producing forklift-ready pallets with minimal human intervention.

Key Features and Benefits

End-to-End Automation: A single, integrated line from material conveying to palletizing.

Dust-Free Operation: The Valve port dry mortar packing machine ensures a clean and environmentally friendly workplace.

High-Speed Production: Capable of achieving outputs of up to 1200 bags per hour, depending on configuration.

Superior Accuracy: Precision weighing systems minimize product giveaway and reduce costs.

Reduced Labor Costs: Automates the most labor-intensive steps, requiring only 1-2 operators for supervision.

Robust Construction: Built with high-quality materials for durability and long-term reliability in demanding industrial environments.

Easy Integration: The line can be customized to fit into your existing factory layout and production process.

Conclusion

Our Automatic Dry Mortar Packing Machine Line, comprising the Valve port dry mortar packing machine, Automatic Bag Placer, Screw Conveyor, and robotic bag palletizer, represents the pinnacle of packaging efficiency. It is the ideal investment for producers looking to scale up their operations, improve product quality, and maintain a competitive edge in the global market.

Ready to revolutionize your packaging process? Contact us today for a free consultation and a customized quotation tailored to your production needs.+8615137127837