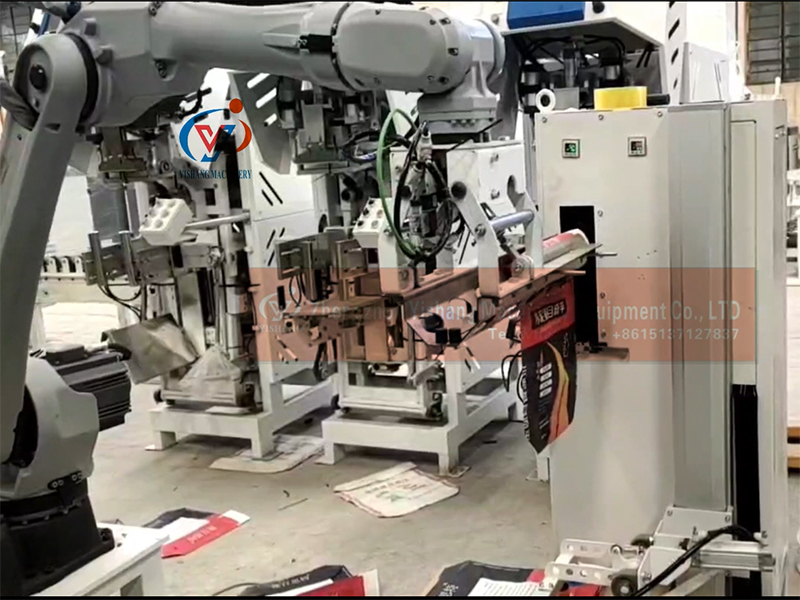

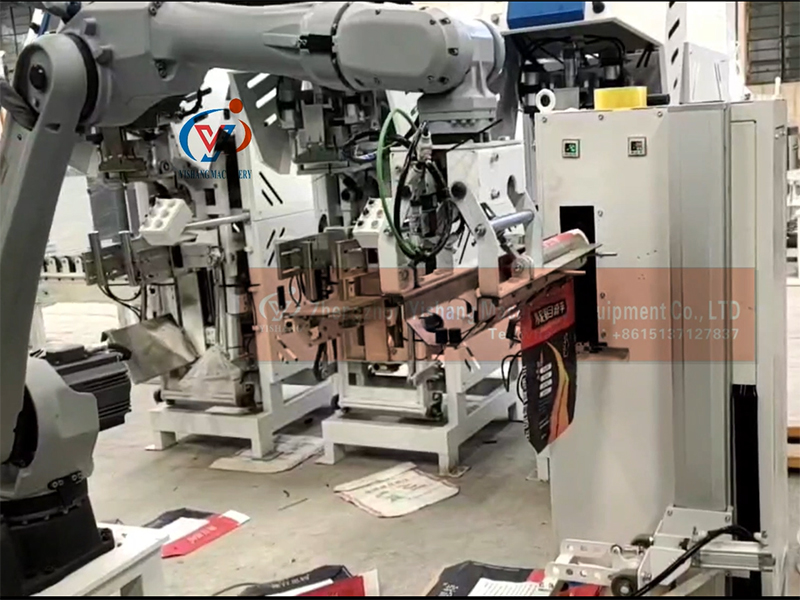

Valve mouth bag auto-sleeving bags machine

Professional Solution for Automatic Valve Bag Sleeving Machine (Dry-Mix Mortar)

Bag Type Compatibility: Valve bags (square/round bottom), standard 20-50kg sizes (e.g., 500×350×100mm).

Material Characteristics: Dry-mix mortar with high dust emission, poor flowability, requiring moisture-proof sealing.

Automation Target: Full automated process (bag picking → opening → sleeving → positioning → sealing) at ≥600 bags/hour.

Bag Storage System:

3D bag rack (1000+ bag capacity) with servo-driven robotic arm/vacuum suction cup dispenser.

Photoelectric sensor ensures single-bag separation to prevent doubling.

Bag Opening Mechanism:

High-pressure air nozzle + mechanical fingers combo, opens valve mouth in 0.5s.

High-sensitivity pressure sensor verifies opening success.

Sleeving & Positioning Module:

6-axis robot (≥10kg payload) with vision system (CCD camera + AI algorithm), ±0.5mm accuracy.

Adaptive gripper for multi-bag types (PE-coated/paper-plastic composite).

Sealing Unit:

Heat-sealing/ultrasonic sealing (200-400℃ adjustable) with leak detection (vacuum test).

Dust Control:

Localized negative-pressure hood + pulse-jet dust collector, ≤5mg/m³ dust concentration (OSHA compliant).

Adaptive Sleeving: Force-feedback robot adjusts gripping force (5-20N adjustable) to prevent tearing.

Self-Diagnostics: PLC-based HMI displays real-time error codes (e.g., low stock, sealing temp anomaly) with remote O&M support.

Quick-Change Design: Modular grippers + parameter memory, bag-type changeover <5 mins (pre-loaded parameters required).

| Parameter | Value |

|---|---|

| Speed | 10-12 bags/min (single station) |

| Positioning Accuracy | ±0.3mm (repeatability) |

| Bag Material | PP/PE/Paper-plastic composite |

| Power Consumption | 15kW (peak) |

| Compressed Air | 0.6MPa, 0.5m³/min |

Building Materials Group: Replaced manual sleeving, achieved <0.5% failure rate + 70% labor cost reduction.

Specialty Mortar Project: ATEX-certified explosion-proof model for epoxy mortar packaging.

Cost-Effective Option: Chinese OEM (e.g., Dongguan brands) ~¥250-400k, 400 bags/hour.

Premium Option: European imports (e.g., Haver & Boecker) ~¥800k-1.2M, 1000 bags/hour with 3D vision alignment.

Whatsapp:++8615137127837

WechatID:+8615137127837

Email:[email protected]

Alibaba Store:

https://zzyishang.en.alibaba.com