Simple dry mortar production line

Our tile adhesive mixing machine dry mortar production line is designed for manufacturing high-quality tile adhesive, wall putty, plaster, and other dry mix products with precision, efficiency, and durability. The complete system includes:

Precision Weighing System

High-Speed Mixing System

Automatic Packaging System

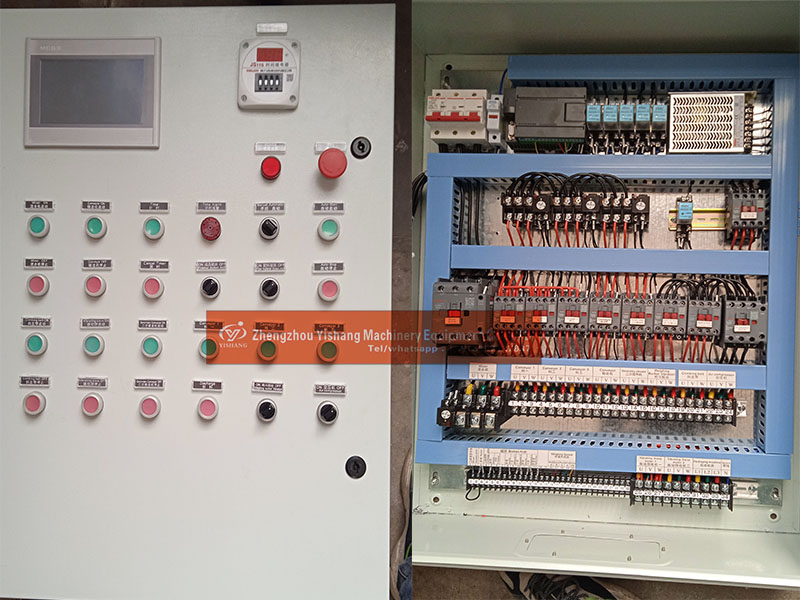

PLC Control Cabinet

Air Compressor (Piston Type)

This integrated production line ensures consistent quality, reduced labor costs, and increased productivity, making it ideal for construction material manufacturers.

Spiral Feeder: Equipped with 5mm thickened wear-resistant blades for smooth and uniform material feeding.

High-Precision Load Cells: Guarantees ±0.5% weighing accuracy for all raw materials.

Aluminum Discharge Valve: Specially designed for powder materials to prevent clogging and ensure smooth flow.

Three-Layer Ribbon Mixer: Ensures quick and thorough mixing in just 3-5 minutes per batch.

Reinforced Structure: Thickened mixing blades and drum walls for longer service life.

ZQ Gear Reducer & Customizable Motor: Provides stable power transmission with options for different motor specifications.

Automatic Valve Packing Machine: Minimizes dust emission while maintaining high filling accuracy (±0.2%).

User-Friendly Operation: Simple controls and easy maintenance reduce downtime.

Touchscreen HMI: Intuitive interface with independent window displays for quick operator training.

Fast Response & Automation: PLC-based system improves efficiency and reduces human error.

Piston-Type Air Compressor: Durable, low-maintenance design for consistent pneumatic performance.

✅ High Accuracy: Precise weighing and mixing for consistent product quality.

✅ Durable Construction: Thickened steel and wear-resistant components for longevity.

✅ Automated Efficiency: Reduces labor costs and increases production speed.

✅ Easy Maintenance: Simplified design for minimal downtime.

✅ Customizable Options: Adjustable motor power, capacity, and packaging solutions.

✔ Tile Adhesive Manufacturing

✔ Wall Putty Production

✔ Dry Mix Plaster & Mortar

✔ Self-Leveling Compounds

✔ Waterproofing & Grout Mixes

Our dry mortar mixing and packaging line is engineered for maximum output with minimal waste. Whether you produce tile adhesive, wall putty, or specialty mortars, our system delivers reliability, precision, and efficiency.

📞 Contact us now for a customized solution tailored to your production needs!+8615137127837

Whatsapp:++8615137127837

WechatID:+8615137127837

Email:[email protected]

Alibaba Store:

https://zzyishang.en.alibaba.com