3-4 tons/hour dry mortar mix plant production line installation instructions

2022-09-25

2022-09-25

Installation of necessary tools and spare supplies for 3-4 tons/hour dry mortar mix production line plant:

1, 100A three-phase four-wire plastic case circuit breaker (connected to the main gate), 63A three-phase miniature circuit breaker two (connected to the main engine and air compressor), 40A three-phase miniature circuit breaker two (connected to two elevators), 4P miniature circuit breaker 40A (connected to the packaging machine), 6 square single core copper wire 10 meters for serial connection of each switch, One small electric box (400*500*200), four 10mm expansion screws, one hammer drill, one 10mm drill bit, 1m guide rail, 12-14, 14-17, 19-22, 22-24 open box wrench, one 250mm adjustable wrench, 10m iron wire, one hand pliers, one wallpaper knife, one flat-head Phillips screwdriver each, 2 rolls of electrical tape, a bucket of butter, a butter gun, a 0.9m3/min air compressor (complete joints), 10mm plastic transparent air pipe 30m, a fast air pipe three, two sets of iron 10mm air pipe joints, a blow gun, 2 rolls of raw material belt.

2. The main motor connection wire is 4 square three-core copper wire, the primary spiral hoist electromechanical wire is 2.5 square three-core copper wire, and the packaging electromechanical wire is 2.5 square four-core copper wire. Cable according to the position of the machine and the distance from the power bus

3. If the reducer of the mixing host is a cycloid reducer, it needs to buy 46# oil (anti-wear hydraulic oil) 4 liters of two barrels.

Installation steps

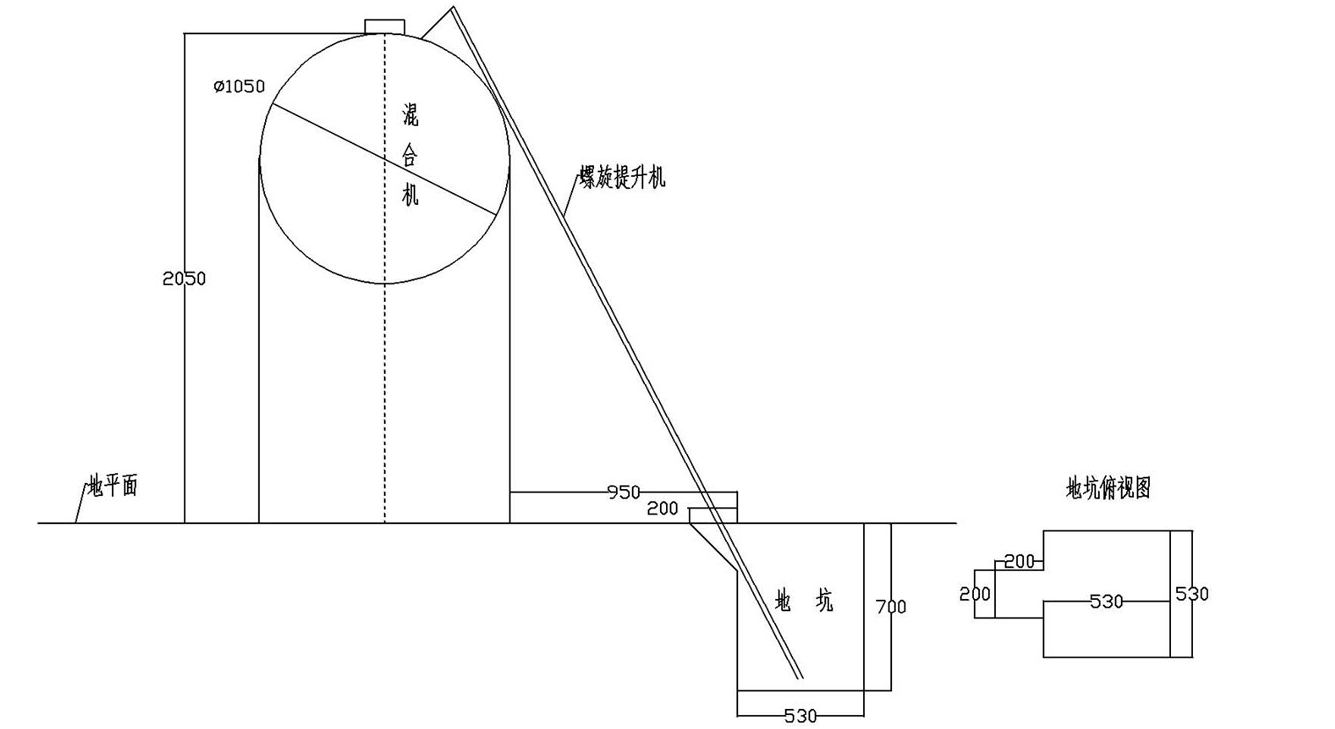

1. According to the layout planning of the user's site, put the multi-functional mixer host machine in the pre-selected place. Note: Select the location of the mixing host to take into account several factors: 1. Raw material storage area and finished product storage area are more convenient. 2. Reserve equipment maintenance channels. The width of a maintenance channel is 0.8 m. (Overall diagram)

2. After the stirring host is placed in place, the center of the feeding port of the stirring host shall be taken as the standard, and the edge of the stirring host shall be measured outward 0.95 meters, where is the edge of the hopper pit of the spiral feeding machine. Bottom pit size is shown in the figure: 0.53m (length) * 0.53m (width) * 0.7m (depth)

Note: After the pit is dug, if water seepage occurs inside the pit, waterproof treatment is required.

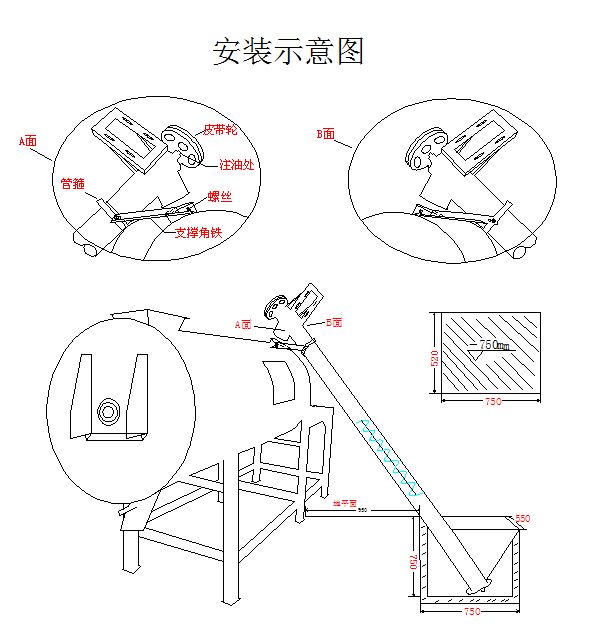

Before digging the pit into the hoist, the hoist bottom butter pipe is good! (as shown in figure)

3. After the pit is dug, put the spiral feeder into the pit, and the hopper of the feeder is horizontal or higher than the ground (the distance is controlled within 10cm). As shown in figure:

4. After putting it in place, connect the screw feeding machine and stirring host machine with the hoop, and tighten the screw. The discharging port of the spiral feeding machine and the feeding port of the mixing host are connected with a soft connection and tied with iron wire. After the connection is good, the other feeding port on the stirring host is tied tightly with a dust-proof and breathable cloth bag (dust bag) to prevent dust. As shown in figure:

5. after connecting, find the manual butterfly valve, and use screws to link the secondary lifting and manual butterfly valve and the outlet of the mixing host. Note: When placing the manual butterfly valve, note that the wrench of the manual butterfly valve is opened when it is upward. As shown in the picture:

6. After putting it in place, link the secondary screw feeder and the finished product bin with the collar. The discharging port of screw feeder and the feeding port of finished product bin are connected with soft connection and tied with iron wire. As shown in figure:

7. After the link is good, cover the other two feeding ports on the finished product bin and another feeding port on the stirring host with dust-proof and breathable fine cloth, and tie it tightly with iron wire.

8. Move the automatic packing machine to the bottom of the finished product warehouse. After the position of the packing machine is adjusted according to the principle of packaging convenience, the cloth bag on the packing machine is taken out and linked to the discharge port of the finished product warehouse, and tied with iron wire. Remember to tie it tightly.

9.link each motor wire. Notice the reverse and reverse. Stirring host stand in the direction of the outlet to see the stirring shaft counterclockwise rotation for positive rotation. The automatic packing machine can follow the arrow direction marked on the shell. The direction of the tip of the spiral blade of the spiral feeder is the positive direction. (Spiral feeding machine from the bottom to the top, the belt counterclockwise rotation is positive).

Precautions for operation

1. When starting the machine, the power supply of the stirring host should be turned on first. The stirring host is strictly prohibited to start under load. Next open a hoist, after the power can be fed. The stirring host will set its own time according to the nature of the material used by its customers. After stirring, open the secondary hoist power source and open the manual butterfly valve at the discharge port of the host.

2. After the material enters the finished product warehouse, open the manual valve below the finished product warehouse, open the automatic packing machine, and then pack.

3, daily maintenance: reducer refueling regularly, the best half a year to replace once, half a year to check the oil level, not enough position timely supplement. Main engine both ends of the bearing and screw feeding machine add butter, add once a week.

Zhengzhou YiShang machinery equipment co., LTD. Has been engaged in the research and development of hybrid mechanical design and manufacturing, our company specializing in the production of the series of equipment are: dry mortar mixer, putty powder mixer, biaxial blade mixing machine, automatic packing scale measurement, single pulse dust collector and so on new equipment, and sand dryer, quartz sand dryer, river sand dryer and a series of equipment. These equipment has been widely used in construction, building materials, chemical, powder, mortar, paint, metallurgy, environmental protection and other industries in the field of first-class enterprises, and has been praised by the majority of users!

Our company specializes in sand dryer, quartz sand dryer, river sand dryer and other complete sets of equipment to provide design, installation and commissioning, and according to the different conditions and requirements of each customer (investment scale, plant conditions, material type, logistics situation, product formula, etc.), to provide professional and reasonable solutions. Please contact Tel/whatsapp: +8615137127837

Whatsapp:++8615137127837

WechatID:+8615137127837

Email:[email protected]

Alibaba Store:

https://zzyishang.en.alibaba.com