Zhengzhou Yishang Unveils "Zero-Downtime" Support: Free Remote Diagnostics for Packing Machine Blockages & Premium Parts Service for tile adhesive dry mortar mixing machine

2025-09-28

2025-09-28

Subheading: Pioneering Dual-Service Model Tackles Most Common Packing Machine Failures with Instant Online Troubleshooting and Guaranteed Genuine Parts

In the high-stakes environment of dry mortar and tile adhesive production, packing machine failure represents a critical bottleneck. When the flow of packaged product stops, the entire production line grinds to a halt, costing businesses thousands per hour in lost productivity. Addressing this urgent industry challenge, Zhengzhou Yishang Machinery Equipment Co., Ltd. has launched an innovative dual-support system. This program provides immediate, free online troubleshooting specifically for packing machine discharge issues, backed by a reliable, paid genuine parts service for physical replacements, ensuring a seamless transition from diagnosis to resolution.

Zhengzhou Yishang's engineers have identified the most frequent culprits behind packing machine failures. Their free online service is strategically designed to guide clients through a systematic, expert-assisted check of these critical points, turning panic into a structured troubleshooting process.

Through a live video call or detailed guided communication, Yishang's technical team immediately assists clients in investigating four key areas, directly referencing the common failure points they've documented:

Material Lump Jam at the Hopper Mouth:

The Problem: Hardened lumps of tile adhesive or dry mortar can form a bridge at the mouth of the packing machine hopper, preventing material from flowing into the weighing and bagging mechanism.

The Free Service Solution: "Our first step is to guide the operator to safely open the lid and inspect the interior," explains a Yishang remote support engineer. "We provide clear instructions to check for material bridges. We also emphasize checking the lid's bottom groove and ensuring it is reinstalled in the exact same position after inspection, as an improper fit can itself contribute to moisture ingress and future lump formation."

2. Incorrect Motor Rotation:

The Problem: The auger motor, which drives the material out of the spout, rotating in the wrong direction will not convey material and can cause damage.

The Free Service Solution: "This is a simple but often overlooked issue," the engineer notes. "We direct the client to locate the rotation arrow marked on the side of the packing machine's motor housing. Using a live video feed, we can verify the actual rotation against the indicated direction. If it's reversed, we can guide them to correct the electrical phase connection, often resolving the issue in minutes."

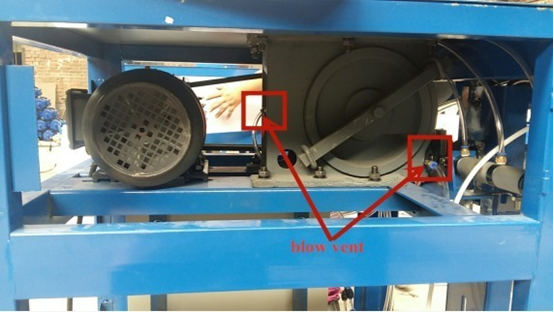

3. Blocked Blowing Nozzle:

The Problem: The air-blowing nozzle, crucial for cleaning the bag-sealing area and ensuring a dust-free operation, can become clogged with fine powder. If integrated into a pneumatic discharge aid system, a blockage can directly affect material flow.

The Free Service Solution: "We help the client locate the blowing nozzle and walk them through the safe procedure to disassemble and inspect it. We demonstrate how to clear the obstruction using compressed air or a fine tool. This immediate guidance prevents minor clogs from escalating into major stoppages."

4. Silo Discharge Obstruction:

The Problem: The root cause may not be the packing machine itself, but a failure of material to even reach it. If material in the overhead storage silo has compacted or arched, it creates a void, starving the packing machine feeder.

The Free Service Solution: "Our diagnostics look at the entire system," states the engineer. "We ask the client to observe whether material is freely falling from the silo into the packing machine inlet. We can then suggest remedial actions, such as activating the silo's vibrators or aeration pads, which can often restart material flow without any physical intervention on the packing machine."

This free, immediate access to expert knowledge empowers operators to become first-line technicians, resolving a significant majority of common packing machine stoppages without cost or delay.

When remote diagnostics confirm a hardware failure—a worn-out auger, a damaged motor, or a clogged valve beyond simple cleaning—Zhengzhou Yishang's paid parts service provides a swift and reliable solution.

1. Precision Parts Identification: Following the online session, the technician can immediately identify the exact replacement part needed—be it a new motor, a specific blowing nozzle assembly, or specialized seals for the hopper lid. This eliminates the guesswork and risk of ordering incorrect components.

2. Guaranteed Genuine OEM Parts: The company stresses the use of original parts. "Using non-OEM parts in a precision machine like a packing system is a false economy," says the Head of After-Sales. "A counterfeit auger might have slightly different dimensions or metallurgy, leading to poor performance, rapid wear, and further damage to the machine housing. Our genuine parts are engineered for perfect fit and optimal longevity."

3. Rapid Global Logistics: Understanding that downtime is expensive, Yishang maintains a strategic inventory of critical packing machine components. Their streamlined global supply chain ensures that clients receive the necessary parts via the fastest available route, with full tracking and customs documentation support.

4. Assisted Installation Support: Even after the part arrives, the support continues. The same technical team that diagnosed the issue remains available to provide free remote guidance during the installation process, ensuring the new part is fitted correctly and calibrated for immediate operation.

Zhengzhou Yishang Machinery's model for supporting its tile adhesive and dry mortar mixing machine and packing systems represents a significant evolution in industrial after-sales service. By directly targeting the most frequent and disruptive issues with free, instant expert guidance, they dramatically reduce machine downtime and build deep client trust.

This approach creates a clear and efficient pathway for resolution:

Step 1: Free Instant Diagnosis. Use expert knowledge to solve the problem remotely.

Step 2: Seamless Parts Provision. If a physical part is needed, ensure a genuine, direct-fit replacement is dispatched immediately.

Step 3: Assisted Restoration. Provide support to get the machine operational again swiftly.

This "Zero-Downtime" support philosophy, blending Free Online Service with Paid Parts Service , establishes Zhengzhou Yishang not just as a machinery manufacturer, but as a dedicated productivity partner for the global building materials industry. +8615137127837

Whatsapp:++8615137127837

WechatID:+8615137127837

Email:[email protected]

Alibaba Store:

https://zzyishang.en.alibaba.com