Fully Automatic Dry Mortar/Tile Adhesive Production Line – Efficient & Reliable Solution

2025-07-09

2025-07-09

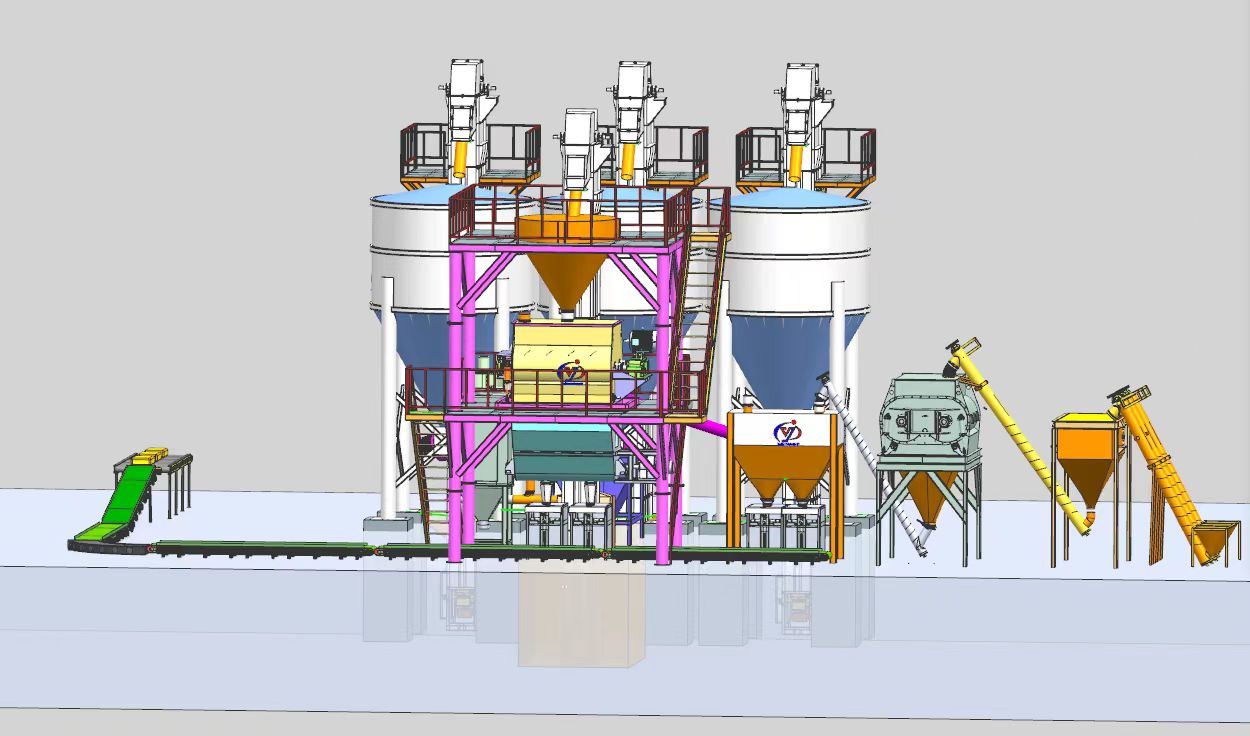

A fully automatic dry mortar/tile adhesive production line is designed for high-efficiency, precision, and consistency in manufacturing dry mix products. This system ensures seamless operations from raw material storage and weighing to mixing and packaging, minimizing human intervention and maximizing productivity.

The production line handles two types of raw materials:

Main materials (e.g., sand, cement)

Additives (chemical powders like cellulose, redispersible polymer powder)

Storage solutions include:

Silos for bulk materials

Big bags or small bags for additives

Automatic feeding systems (screw conveyors, pneumatic conveying)

Accurate weighing is critical for product quality. The system includes:

Loss-in-weight feeders for continuous dosing

Batch weighing scales for precise measurement

High-precision sensors to ensure consistency

After weighing, materials are lifted to the mixer via:

Bucket elevators (for vertical transport)

Screw conveyors (for horizontal transport)

Efficiency depends on selecting the right weighing and lifting equipment to minimize downtime.

The mixing stage determines product uniformity. Common mixer types:

Twin-shaft paddle mixer (gravity-free mixer) – Ideal for homogeneous blending

Single-shaft ploughshare mixer – Suitable for high-speed mixing with additives

Both ensure fast mixing, no dead zones, and high output.

The line includes automated packaging for efficiency:

Automatic bag placing (self-opening bags)

Automatic filling (controlled by weighing system)

Automatic palletizing (stacking bags neatly)

Automatic stretch wrapping (for secure transport)

Complete turnkey solution – From design to installation

High automation – Reduces labor costs & human error

Customizable configurations – Adaptable to different production needs

Energy-efficient & durable – Ensures long-term reliability

An automatic dry mortar/tile adhesive production line enhances productivity, accuracy, and profitability. The key to efficiency lies in precise weighing, fast material lifting, and high-performance mixing.

Looking for a reliable supplier? We provide complete production line solutions tailored to your needs. Contact us today for a customized proposal!+8615137127837

Whatsapp:++8615137127837

WechatID:+8615137127837

Email:[email protected]

Alibaba Store:

https://zzyishang.en.alibaba.com